Products

Chip Resistor

Chip Resistor

Data Sheet

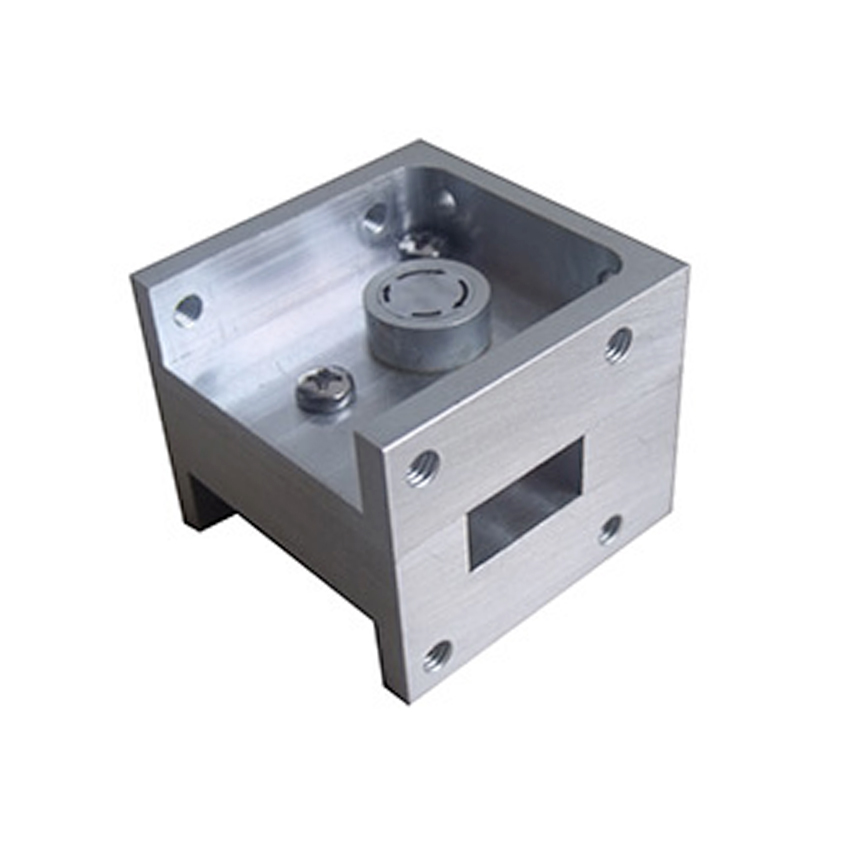

| Power (W) |

Dimension (unit: mm) | Substrate Material | Configuration | Data Sheet(PDF) | ||||

| A | B | C | D | H | ||||

| 2 | 2.2 | 1.0 | 0.5 | N/A | 0.4 | BeO | FigureB | RFTXX-02CR1022B |

| 5.0 | 2.5 | 1.25 | N/A | 1.0 | AlN | FigureB | RFTXXN-02CR2550B | |

| 3.0 | 1.5 | 0.3 | 1.5 | 0.4 | AlN | FigureC | RFTXXN-02CR1530C | |

| 6.5 | 3.0 | 1.00 | N/A | 0.6 | Al2O3 | FigureB | RFTXXA-02CR3065B | |

| 5 | 2.2 | 1.0 | 0.4 | 0.6 | 0.4 | BeO | FigureC | RFTXX-05CR1022C |

| 3.0 | 1.5 | 0.3 | 1.5 | 0.38 | AlN | FigureC | RFTXXN-05CR1530C | |

| 5.0 | 2.5 | 1.25 | N/A | 1.0 | BeO | FigureB | RFTXX-05CR2550B | |

| 5.0 | 2.5 | 1.3 | 1.0 | 1.0 | BeO | FigureC | RFTXX-05CR2550C | |

| 5.0 | 2.5 | 1.3 | N/A | 1.0 | BeO | FigureW | RFTXX-05CR2550W | |

| 6.5 | 6.5 | 1.0 | N/A | 0.6 | Al2O3 | FigureB | RFTXXA-05CR6565B | |

| 10 | 5.0 | 2.5 | 2.12 | N/A | 1.0 | AlN | FigureB | RFTXXN-10CR2550TA |

| 5.0 | 2.5 | 2.12 | N/A | 1.0 | BeO | FigureB | RFTXX-10CR2550TA | |

| 5.0 | 2.5 | 1.0 | 2.0 | 1.0 | AlN | FigureC | RFTXXN-10CR2550C | |

| 5.0 | 2.5 | 1.0 | 2.0 | 1.0 | BeO | FigureC | RFTXX-10CR2550C | |

| 5.0 | 2.5 | 1.25 | N/A | 1.0 | BeO | FigureW | RFTXX-10CR2550W | |

| 20 | 5.0 | 2.5 | 2.12 | N/A | 1.0 | AlN | FigureB | RFTXXN-20CR2550TA |

| 5.0 | 2.5 | 2.12 | N/A | 1.0 | BeO | FigureB | RFTXX-20CR2550TA | |

| 5.0 | 2.5 | 1.0 | 2.0 | 1.0 | AlN | FigureC | RFTXXN-20CR2550C | |

| 5.0 | 2.5 | 1.0 | 2.0 | 1.0 | BeO | FigureC | RFTXX-20CR2550C | |

| 5.0 | 2.5 | 1.25 | N/A | 1.0 | BeO | FigureW | RFTXXN-20CR2550W | |

| 30 | 5.0 | 2.5 | 2.12 | N/A | 1.0 | BeO | FigureB | RFTXX-30CR2550TA |

| 5.0 | 2.5 | 1.0 | 2.0 | 1.0 | AlN | FigureC | RFTXX-30CR2550C | |

| 5.0 | 2.5 | 1.25 | N/A | 1.0 | BeO | FigureW | RFTXXN-30CR2550W | |

| 6.35 | 6.35 | 1.0 | 2.0 | 1.0 | BeO | FigureC | RFTXX-30CR6363C | |

Overview

Chip Resistor, also known as Surface Mount Resistor, is widely used resistors in electronic devices and circuit boards. Its main feature is to be directly installed on the circuit board through surface mount technology (SMD), without the need for perforation or soldering of pins.

Compared with traditional resistors, the chip resistors produced by our company have the characteristics of smaller size and higher power, making the design of circuit boards more compact.

Automated equipment can be used for mounting, and chip resistors have higher production efficiency and can be produced in large quantities, making them suitable for large-scale manufacturing.

The manufacturing process has high repeatability, which can ensure specification consistency and good quality control.

Chip resistors have lower inductance and capacitance, making them excellent in high-frequency signal transmission and RF applications.

The welding connection of chip resistors is more secure and less susceptible to mechanical stress, so their reliability is usually higher than that of plug-in resistors.

Widely used in various electronic devices and circuit boards, including communication devices, computer hardware, consumer electronics, automotive electronics, etc.

When selecting chip resistors, it is necessary to consider specifications such as resistance value, power dissipation capacity, tolerance, temperature coefficient, and packaging type according to application requirements